If your supplier only talks about “boards,” you might be buying a future snag list.

UK balconies tend to be reviewed as assemblies: slip method, drainage, ventilation, edges, wind restraint, and cleaning plan.

TL;DR — what’s worth asking (before anyone signs off)

- Slip needs a named method + the exact texture: “slip resistant” alone is marketing, not a spec. Background: HSE slips overview.

- Define barefoot vs shod routes: a balcony can have both (door threshold route vs lounge zone).

- Drainage + ventilation: if water lingers and drying is slow, performance claims become irrelevant.

- CopoSurface data (for submittals): wet slip AS 4586 P5 / R13; MOR ≈ 44 MPa, MOE ≈ 2600 MPa; absorption <1%, swell <0.1%; freeze–thaw/high–low cycles ~±10%. See Why CopoSurface.

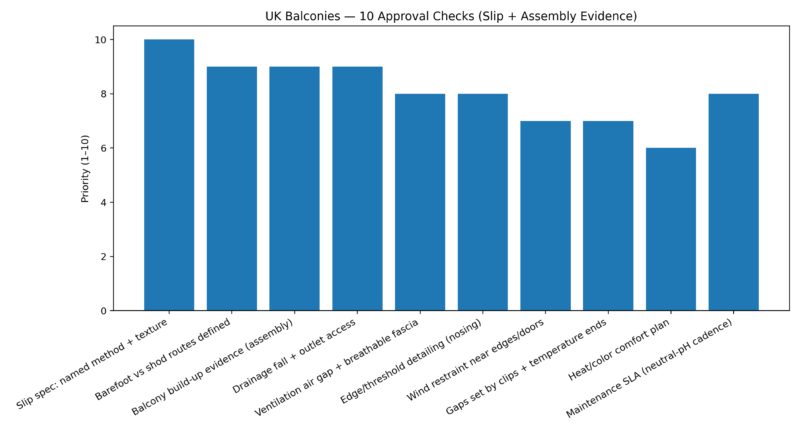

10 Balcony Approval Checks (copy into your RFQ)

| # | Check | What to verify | Why it matters |

|---|---|---|---|

| 1 | Slip spec = method + texture | Named test method and result tied to the exact emboss supplied | Stops “paper safety” |

| 2 | Barefoot vs shod routes | Map the routes: door-to-seating (shoes) vs barefoot zones (if any) | Different risks, different expectations |

| 3 | Assembly evidence | Evidence references the build-up (board + subframe/pedestals + substrate) | Balconies are judged as assemblies |

| 4 | Drainage fall + outlet access | 1–2% falls to outlets; inspection access shown; avoid blocking drains | Controls ponding and algae risk |

| 5 | Ventilation + breathable fascia | ≥50 mm air gap; fascia breathes; avoid boxed corners | Drying time = real-world safety |

| 6 | Edges & thresholds | Picture-frame/bullnose/nosing at doors and steps | Where trips and chips happen first |

| 7 | Wind restraint near edges/doors | Perimeter restraint rows; fixing schedule; door edge conditions | Movement control and durability |

| 8 | Gaps (clips + temperature) | Clip-controlled side gaps (4–6 mm); end gaps set by temperature | Clean lines and expansion tolerance |

| 9 | Heat/color comfort plan | Light/mid matte tones; shade plan if full sun | Comfort + fewer film issues |

| 10 | Maintenance SLA (neutral-pH) | Named products + cadence + responsibility (owner vs FM contractor) | Grip depends on film control |

Start from real installs: Project Gallery ·

Pick a system: Ecosolid Decking ·

Common questions: FAQ ·

Product notes: About Product.

FAQ — quick, copyable answers

Is “R13” enough to approve a balcony?

It’s useful evidence, but approvals tend to be about the whole assembly: drainage, drying time, ventilation, edges and the cleaning plan.

Why do balconies “feel” slippery even if tests look good?

Films (sunscreen, oils, airborne grime) plus slow drying are common culprits. That’s why a neutral-pH cadence and ventilation details matter.

What’s the fastest way to normalise quotes?

Require a line-item system quote: boards, subframe/pedestals, edges, drainage/ventilation notes, wind restraint and maintenance cadence.