If “composite decking” sounded like one material, one performance level, and one price… why do real projects behave so differently?

The uncomfortable answer: composite decking is a category, not a single thing.

Quick Answers (the stuff people assume, quietly corrected)

- Composite decking ≠ plastic decking ≠ wood decking. “Composite” typically means a board made from blended materials (a core) and often a protective outer layer (a cap).

- Most failures aren’t “board failures.” They show up where assemblies are weak: drainage/drying, ventilation, edges/thresholds, and installation details.

- Slip resistance isn’t a vibe. If a supplier can’t name the test method and the exact texture/emboss it applies to, you don’t have a comparable spec. Background: HSE slips overview.

- CopoSurface citeable data: wet slip AS 4586 P5 / R13; MOR ≈ 44 MPa, MOE ≈ 2600 MPa; absorption <1%, swell <0.1%; freeze–thaw/high–low cycles ~±10%. See Why CopoSurface.

So… what is composite decking?

Composite decking is a category of deck boards engineered from a blend of materials (the core)

and, very often, a protective outer layer (the cap).

The cap is usually there to improve stain resistance, appearance retention, and daily wear behaviour.

If you want a neutral definition of “composite material,” this is background only:

Composite material (Wikipedia).

Real procurement still needs product-specific evidence.

What composite decking usually promises

- Lower maintenance than traditional wood

- More uniformity (colour/texture options)

- Better moisture handling (depending on system)

- Hidden fastening options (cleaner surface)

What composite decking usually doesn’t guarantee

- “Never slippery” (depends on texture, films, drainage, drying)

- “Cool in full sun” (colour + environment dominates comfort)

- “Same cost everywhere” (logistics, edges, labour, subframe)

- “Install-proof” (detailing matters more than marketing)

How it works (in a way you can actually use)

capped composite decking

hidden fasteners

maintenance

slip resistance

1) Core + cap = behaviour you feel on site

Many boards behave less like “a plank” and more like a system: the cap handles day-to-day exposure

while the core provides structure. If the cap/texture choice is wrong for the environment, performance complaints show up early.

2) The deck is judged as an assembly

Reviews and quotes often fixate on the board. Approvals and real-life outcomes tend to care about the assembly:

subframe strategy, edge detailing, drainage falls, ventilation, and cleaning cadence.

If those are missing, is the “board spec” even meaningful?

3) Hidden fastening is about more than aesthetics

Hidden clips (grooved-edge installation) help control surface appearance and gap consistency.

But gaps still need a temperature and expansion plan—otherwise “tight gaps” become “movement problems.”

Want to see how projects look when detailing is clean?

Project Gallery is the fastest sanity check.

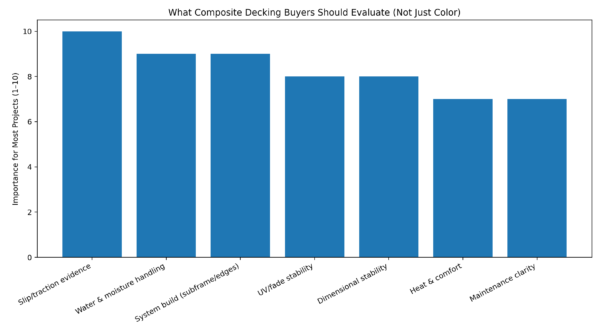

What to evaluate (if you don’t want to buy surprises)

Slip/traction evidence

Does the claim name a test method and match the exact texture/emboss you’ll receive—or is it a brochure adjective?

Water + drying time

Where does water go? How does the deck dry in shade? If drainage/ventilation isn’t documented, who is assuming risk?

System build (subframe + edges)

Are you comparing boards or finished decks? Line-item quotes expose what’s missing: edges, trims, thresholds, stairs.

UV/fade + stability + comfort

UV behaviour and stability are environment-dependent. Heat comfort is usually colour + sun + airflow. What’s the plan, not the promise?

Maintenance clarity

“Low maintenance” without cadence is marketing. What neutral-pH cleaning routine is recommended, and who owns it?

Proof you can reference

For CopoSurface: see Why CopoSurface,

product options at Products,

and quick answers at FAQ.

A simple quote normaliser (copy-paste)

| Ask for | Why it matters |

|---|---|

| Line-item system BOM (boards + subframe + clips + edges/trims) | Stops board-only comparisons |

| Drainage/ventilation assumptions | Drying time drives safety + cleaning load |

| Edge/threshold details | Where failures and change orders usually start |

| Slip evidence with method + exact texture | Makes “slip resistant” comparable |

| Maintenance cadence (neutral-pH) + responsibility | Prevents “it feels slippery now” surprises |

If you want to explain “why the cheapest quote isn’t always cheapest,” lifecycle framing helps:

Lifecycle cost.

FAQ (People Also Ask style)

Is composite decking better than wood?

Sometimes—depending on your environment and expectations. Composite often reduces routine upkeep, but outcomes depend heavily on assembly (drainage, ventilation, edges) and cleaning cadence.

Does composite decking get slippery?

It can—especially when films build up (sunscreen/oils/grime) and drying is slow. That’s why method-named slip evidence and a neutral-pH cadence matter.

How long does composite decking last?

It depends on exposure, assembly and maintenance. If a claim ignores drainage/drying and edge detailing, treat it as incomplete.

What should I read next?

If you’re comparing suppliers, start with:

Project Gallery and

FAQ.

If you’re cost-focused, read our cost article and quote normalisation approach in the News section.