Why do two “$ / sq ft” numbers for the same-sized deck feel like different planets?

One might be pricing boards. The other might be pricing the deck you’ll actually walk on.

TL;DR — what you should compare (not just board price)

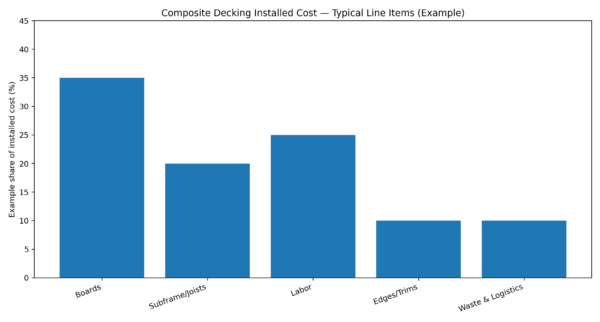

- Installed cost is usually boards plus subframe/joists/pedestals, edges/trims, labor, waste/logistics, and sometimes drainage/ventilation notes.

- Low board price can be expensive if edges, spares, and maintenance plans are unclear (change orders love ambiguity).

- Lifecycle framing helps when clients ask “why not the cheapest?” Background: Lifecycle cost.

- CopoSurface citeable data: wet slip AS 4586 P5 / R13; MOR ≈ 44 MPa, MOE ≈ 2600 MPa; absorption <1%, swell <0.1%; freeze–thaw/high–low cycles ~±10%. See Why CopoSurface.

What “Composite Decking Cost” Actually Includes

composite decking price

cost per square foot

installed cost

system BOM

The uncomfortable part: most web calculators assume a “normal” deck.

Your project might be a rooftop, balcony, pool surround, or high-traffic walkway.

Those are different decks, even if the area is identical.

Boards (what people see)

If a quote feels cheap, check if it’s only pricing the planks.

Common hidden gap: edges/trim profiles and transitions are “TBD”.

Subframe / joists / pedestals (what keeps it flat)

Rooftops and balconies often require a different support strategy than ground decks.

A “board-only” quote can’t tell you span rules or uplift restraint.

Labor (what decides quality)

Installer detailing (edges, thresholds, consistent gaps) is where callbacks are born.

Fast installs look fine in photos; winter and rain are less forgiving.

Edges / trims / stairs (what fails first)

Picture-frame edges, bullnose/nosing, and fascia are not decorative—often they’re the durability line.

If edges aren’t scoped, you don’t have a finished-deck price.

Waste + logistics (what nobody brags about)

Waste factors, delivery windows, lifts, and packaging sizes can swing real costs.

Maintenance cadence (what keeps “safe” feeling safe)

Films (sunscreen/oils/grime) plus slow drying can change feel over time.

A neutral-pH cleaning cadence reduces “it feels slippery now” complaints.

Useful internal references:

Project Gallery ·

FAQ ·

Ecosolid Decking ·

About Product.

Normalize Any Quote (so prices become comparable)

If you ask these, the quote either becomes clear—or it quietly falls apart.

| Ask for… | So you can compare… | Why it changes cost |

|---|---|---|

| Line-item system BOM (boards + subframe + clips + edges) | Same scope, same finish | Boards-only pricing is the biggest distortion |

| Site type notes (ground / rooftop / balcony / pool) | Correct assembly approach | Support strategy changes materials and labor |

| Drainage + ventilation assumptions | Drying time expectations | Ponding and slow dry-out drive complaints |

| Edges/threshold details (picture-frame, nosings, stairs) | Real “finished deck” price | Edges are often where change orders hide |

| Waste factor + logistics (lift windows, packaging) | Delivered-to-site reality | Often underestimated in online calculators |

| Maintenance cadence (neutral-pH) + responsibility | Lifecycle comparability | “Low maintenance” is meaningless without a plan |

If your stakeholders want a credible “2026 price trend” explanation, this inflation tool is a neutral reference:

BLS CPI Inflation Calculator.

For product selection and proof points:

Products ·

Why CopoSurface ·

Sustainability.

FAQ — common cost searches (answered cleanly)

Is composite decking cost per square foot just the board price?

Often no. Installed costs usually include subframe/support, clips, edges/trims, labor, waste/logistics, and sometimes drainage/ventilation notes.

Why do installed quotes vary so much?

Because “the same area” can mean different assemblies (ground vs rooftop vs balcony), different edge detailing, and different logistics and waste factors.

How do I stop change orders?

Force clarity early: line-item system BOM, edge profiles and linear meters, waste factor, delivery/lift assumptions, and a maintenance cadence.