Ever notice how many reviews sound confident… yet never mention drainage, slip test methods, or the subframe?

If nobody wrote it down, did it ever get checked?

TL;DR — what reviews usually miss

- Reviews judge boards; sites live or die on assemblies (subframe, edges, drainage, ventilation).

- Slip claims need a named method + exact texture: “anti-slip” without a method/texture is not comparable. Background: HSE slips.

- Most “slippery” stories are film + slow drying: sunscreen/oils + shade + poor drainage.

- CopoSurface citeable data: wet slip AS 4586 P5 / R13; MOR ≈ 44 MPa, MOE ≈ 2600 MPa; absorption <1%, swell <0.1%; freeze–thaw/high–low cycles ~±10%. See Why CopoSurface.

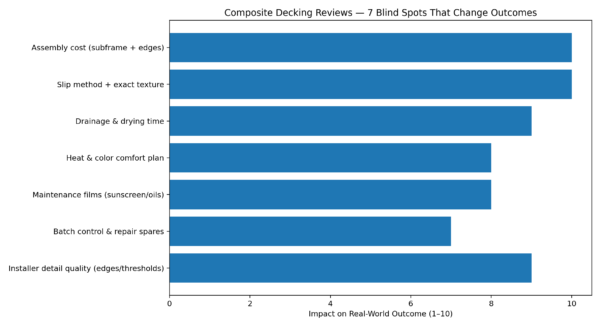

The 7 Blind Spots (and the question to “quietly” ask)

slip evidence

assembly

drainage

maintenance films

batch control

1) Assembly cost (subframe + edges)

What reviews say: “$X per sq ft.”

What matters: rails/pedestals, clips, trims, logistics, waste.

Quiet question: “Was that price boards-only… or a full system with edges and subframe?”

2) Slip method + exact texture

What reviews say: “Not slippery.”

What matters: named method (Pendulum/DCOF/DIN 51097) tied to the exact emboss.

Quiet question: “Which test method applies to the texture they installed?”

3) Drainage & drying time

What reviews say: “Looks great after rain.”

What matters: falls, outlet access, ventilation, breathable fascia.

Quiet question: “Where does water go—and how fast does it dry in shade?”

4) Heat & color comfort

What reviews say: “Love the dark color.”

What matters: comfort in sun, where people actually stand barefoot.

Quiet question: “Did they test it at noon in peak summer?”

5) Maintenance films (sunscreen/oils)

What reviews say: “Low maintenance.”

What matters: neutral-pH cleaning cadence to stop films changing grip/appearance.

Quiet question: “What’s their actual cleaning routine—weekly, monthly, or never?”

6) Batch control & repair spares

What reviews say: “Easy to replace later.”

What matters: batch IDs, spares strategy, trims availability for corners/steps.

Quiet question: “Did they keep spare boards from the same batch?”

7) Installer detailing (edges/thresholds)

What reviews say: “Installer was fast.”

What matters: edges, nosings, thresholds, consistent gaps—where failures start.

Quiet question: “How do the edges look after one winter?”

Want reference installs instead of review snippets?

See: Project Gallery ·

Core questions: FAQ ·

Products: All Products ·

Decking option: Ecosolid Decking.

How to read reviews like a spec reviewer (in 60 seconds)

| When a review says… | Translate it to… | Ask for… |

|---|---|---|

| “Great price” | Unknown scope | Line-item system quote (boards + subframe + edges + logistics + waste) |

| “Not slippery” | Not a method | Named slip method + exact texture/emboss reference |

| “Low maintenance” | Unspecified cleaning | Neutral-pH cleaning cadence + who owns the SLA |

| “Holds up well” | Unknown exposure | Sun/shade context, drainage details, edge detailing photos |

If you prefer a lifecycle framing over sticker price, this is useful background:

Lifecycle cost.

FAQ — what people actually search

Are composite decking reviews trustworthy?

Some are. The reliable ones describe the assembly, exposure (sun/shade), drainage, and an actual cleaning cadence—not just color opinions.

What’s the fastest way to compare brands using reviews?

Ignore brand names first. Score reviews by whether they mention: assembly scope, slip method+texture, drainage/drying, edges, and maintenance routine.

Why do some decks feel slippery after a few months?

Often film build-up (sunscreen/oils) plus slow drying in shade. A neutral-pH cadence and ventilation details matter more than “scratch stories.”