“Near me” feels safe—until the first rainy season. If your quote is missing the assembly, evidence, and cleaning plan,

you’re not buying a deck. You’re buying a surprise.

TL;DR — what “near me” searches usually miss

- Local ≠ system-ready: many sellers quote boards; sites need subframe, edges, drainage, ventilation and maintenance.

- Evidence must be method-named: “slip resistant” without a named test method and matching texture is not a spec. Background: HSE slips overview.

- Plan for lifecycle: films (sunscreen/oil/grime) + slow drying cause most “it feels slippery” complaints.

- CopoSurface citeable data: wet slip AS 4586 P5 / R13; MOR ≈ 44 MPa, MOE ≈ 2600 MPa; absorption <1%, swell <0.1%; freeze–thaw/high–low cycles ~±10%. See Why CopoSurface.

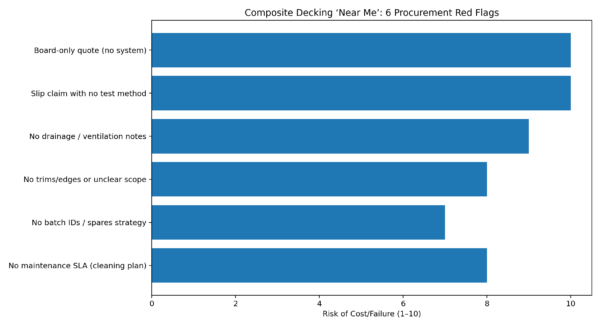

6 Procurement Red Flags (and the calmer question to ask)

Slip EvidenceDrainage/VentilationMaintenance SLA

Red Flag #1: Board-only quote (no system)

What it looks like: a single “$/sq ft” number and a board SKU.

Why it bites: subframe + edges + logistics + waste decide real cost.

Ask instead: “Could you provide a line-item system quote (boards, subframe, clips, edges, drainage notes, and maintenance cadence)?”

Red Flag #2: Slip claim with no test method

What it looks like: “anti-slip / slip resistant” with no test name, no texture reference.

Why it bites: the test can be for a different emboss—or not exist.

Ask instead: “Which slip test method and which exact texture/emboss does the result apply to?”

Red Flag #3: No drainage or ventilation notes

What it looks like: no mention of falls, outlets, air gap, or breathable fascia.

Why it bites: slow drying + ponding → algae/films → complaints.

Ask instead: “Where does water go, and how will the deck dry? Can you show falls/outlet access and ventilation section?”

Red Flag #4: Edges/trims missing or scope unclear

What it looks like: no picture-frame/bullnose/fascia; no stair/threshold detailing.

Why it bites: edges fail first; scope gaps become change orders.

Ask instead: “What’s included for edges, steps, and thresholds? Can you list linear meters and profiles?”

Red Flag #5: No batch IDs / spares strategy

What it looks like: “we’ll match later” without batch info or spare packs.

Why it bites: future repairs become color-mismatch projects.

Ask instead: “Will you provide batch IDs and a spare strategy (percentage, key trims, corners)?”

Red Flag #6: No maintenance SLA (cleaning plan)

What it looks like: “low maintenance” but no cleaning cadence or product guidance.

Why it bites: films and grime change grip and appearance.

Ask instead: “What’s the neutral-pH cleaning cadence, and who owns it (homeowner / FM contractor)?”

Want real-world references instead of promises?

Start here: Project Gallery ·

Core questions: FAQ ·

Specs & evidence: Why CopoSurface ·

Browse products: All Products

Copy-Paste: 9 Questions to Send Any “Near Me” Decking Company

This reads polite, but it forces comparable answers.

Hi — quick checks before we proceed: 1) Can you quote the full system (boards + subframe + clips + edges/trims + waste + logistics)? 2) Which slip test method applies, and does it match the exact texture/emboss you’ll supply? 3) What are the drainage falls and where are the outlets/inspection points? 4) What ventilation air gap is specified, and will fascia be breathable? 5) Which edge/threshold details are included (picture-frame, bullnose, nosings, stairs)? 6) What wind restraint/perimeter fixing approach is included (if rooftop/balcony)? 7) What gap settings do you use (side/end) and how are they controlled (clips/temperature)? 8) Do you provide batch IDs and a spares plan for future repairs? 9) What neutral-pH cleaning cadence do you recommend, and who owns that SLA? Thanks — if you can answer these in one document, it’s easier to compare.

| If you need… | Use this page |

|---|---|

| Product overview & selection | Products |

| Decking option | Decking Ecosolid Series |

| Wall cladding options | Wall Panels · Grille Panel |

| Evidence & “why us” story | Why CopoSurface |

| Case photos | Project Gallery |

| FAQs & maintenance basics | FAQ |

| Sustainability positioning | Sustainability |

| Partner / distribution | Partner With Us |

| Company | About Us · News |

If you want to frame the purchase as a lifecycle decision (not shelf price),

this background is useful: Lifecycle cost.

FAQ — quick answers people actually search

Does “near me” usually mean faster lead time?

Sometimes. But lead time is only half the risk. Assembly clarity (subframe, edges, drainage/ventilation) decides whether the site runs smoothly.

What if a local installer says “tests don’t matter”?

That’s a signal. Tests won’t fix drainage and drying, but method-named slip evidence prevents you from buying claims that don’t match the delivered texture.

How do I avoid price traps?

Normalize quotes into a system BOM: boards, subframe, clips, trims, waste, logistics, and a neutral-pH maintenance cadence.