Slippery decks aren’t “bad material.” They’re predictable: wrong finish, no named slip method, poor drainage/ventilation, gaps clogged, or films from the wrong cleaner. Fix what fails first.

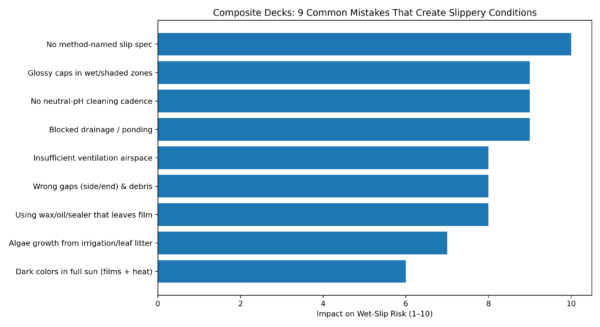

9 Common Mistakes That Make Composite Decks Slippery (and How to Fix Them)

TL;DR — why decks get slippery

- No method, no comparability: “slip resistant” without a test name isn’t a spec. Name Pendulum/DCOF/DIN 51097 and match the texture. Background: HSE overview.

- Finish & film: glossy caps show sunscreen/oil films; matte/open-grain with neutral-pH cleaning is steadier.

- Water management: 1–2% falls + ≥50 mm ventilation + clip-controlled gaps keep surfaces dry and clean.

- CopoSurface data you can cite: wet slip AS 4586 P5 / R13; MOR ≈ 44 MPa, MOE ≈ 2600 MPa; absorption <1%, swell <0.1%; freeze–thaw/high–low cycles ~±10%. See Why CopoSurface.

9 Mistakes (what it looks like → why risky → how to fix)

| # | What it looks like | Why it’s slippery | Fix it with |

|---|---|---|---|

| 1 | Spec says “slip resistant” only | No method/texture = untestable claim | Name Pendulum/DCOF/DIN 51097 on the exact emboss |

| 2 | Glossy cap in wet/shaded zones | Films sit on gloss, feel slick | Use matte/open-grain textures at pools/walkways |

| 3 | No neutral-pH cleaning plan | Oils/sunscreen leave films | Write a neutral-pH cadence into maintenance SLA |

| 4 | Ponding after rain | Algae buildup + film retention | 1–2% falls to outlets; keep pedestals off drains |

| 5 | Boxed fascia/no airspace | Surface dries slowly; odor/algae | ≥50 mm ventilation; fascia must breathe |

| 6 | Gaps clogged with debris | Water & dirt sit on the board | Clip-controlled 4–6 mm gaps; periodic clearing |

| 7 | Wax/oil/sealer applied for “shine” | Leaves a slick film layer | Avoid film-forming products; neutral-pH clean instead |

| 8 | Algae near planters/irrigation | Persistent wet zone + organics | Redirect irrigation; increase sun/air; adjust cleaning |

| 9 | Very dark tones in full sun | Heat + soft films, comfort drops | Select light/mid tones; add shade where possible |

Need examples? See Project Gallery. Choosing finishes: Ecosolid Decking. Policy/data: Why CopoSurface · Sustainability · Answers: FAQ.

FAQ — quick, copyable answers

Can I “polish” composite to restore gloss?

Don’t. Polishes/waxes leave films that kill wet grip. Restore by neutral-pH cleaning and choose matte/open-grain finishes.

Is pressure washing the solution?

Use carefully and follow manufacturer limits; aggressive washing can drive dirt into gaps and damage edges. Routine neutral-pH cleaning is safer.

Do I need a formal cleaning SLA?

Yes—assign cadence, products and ownership. Wet grip depends on keeping films off the surface.